Roth McFarlane Hand and Upper Limb Centre (HULC) in London, Ontario is using Altair SimSolid™ to evaluate the biomechanics of bone stresses. Under the direction of Dr. Louis Ferreira, PhD, human bone specimens are CT scanned with a high-resolution scanner which preserves much of the internal trabecular bone’s micro structure geometry. These models are imported into SimSolid for simulated mechanical testing that matches the physical model. SimSolid allows us to augment measurements from our experimental models that would otherwise be prohibitive or impossible to measure directly on the specimen.

Here are a few examples from their research.

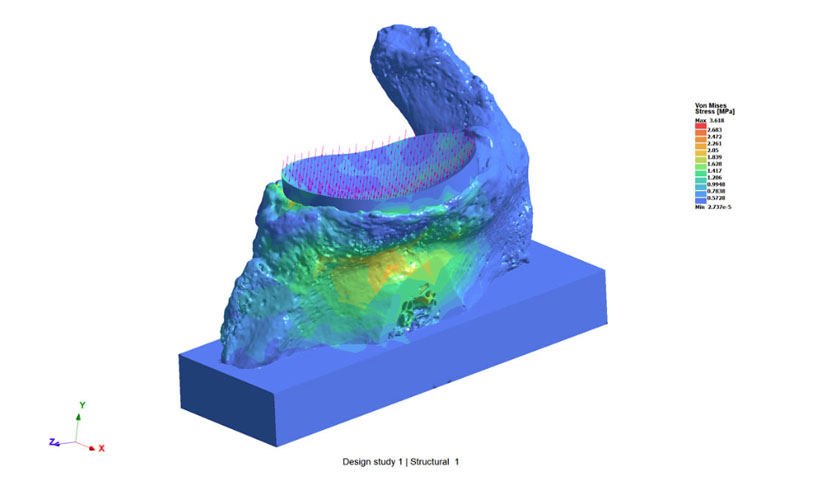

Shoulder Joint Implant

Patients with shoulder arthritis are often treated surgically by replacing the diseased joint with implants. This model shows the shoulder blade (scapula) with the shoulder socket replaced by a glenoid implant. Experimental loading conditions are simulated here through the arm implant components (not shown). This model allows us to simulate how different implant types influence bone stresses, which can influence longevity of the surgical procedure. SimSolid allows us testing of a high resolution bone models from a 60 micron resolution CT scan. Model created by Nikolas Knowles, MESc.

Figure 1 – Stresses on scapula bone with glenoid implant shown

Figure 1 – Stresses on scapula bone with glenoid implant shown

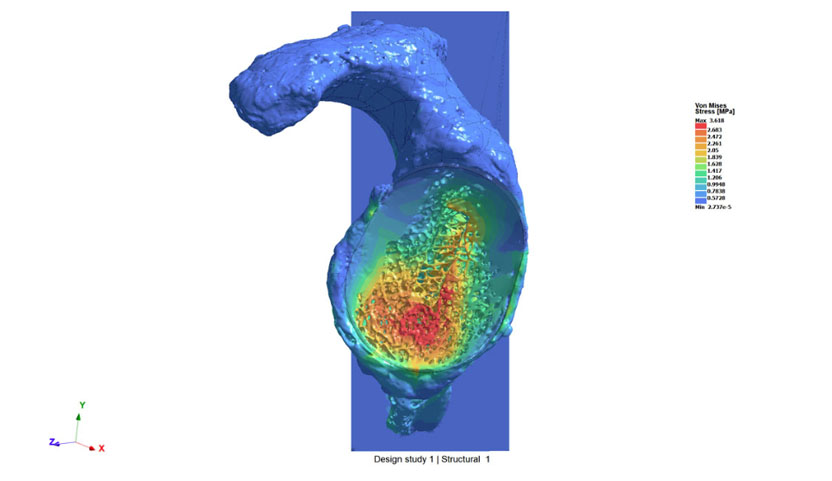

Figure 2 – Stresses on scapula bone with glenoid implant hidden

Figure 2 – Stresses on scapula bone with glenoid implant hidden

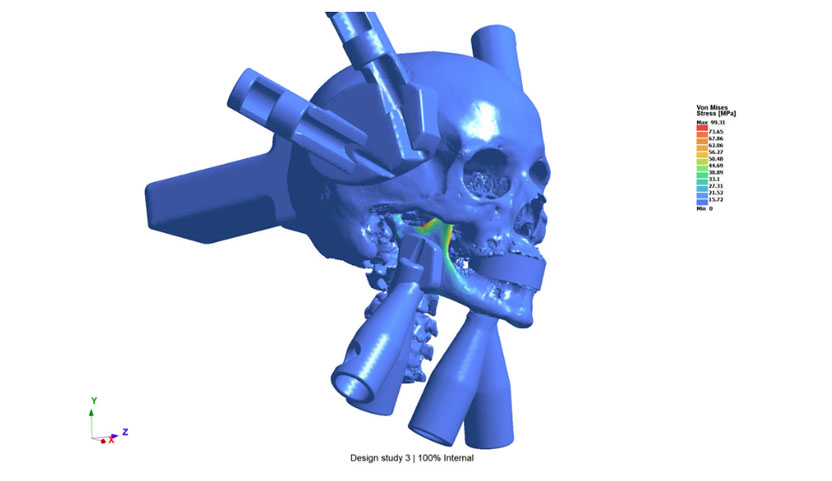

Human Skull

An experimental model uses 3D printed piston mounts to recreate muscle lines of action on a cadaveric human head. Strain gauges on the bone surface measure bone strains generated by biting forces. This experiment is recreated in SimSolid in order to measure bone strains in areas where strain gauges could not be placed on the specimen. The bone model was created from a CT scan. This model allows us to study the effects of injury and surgical implants like fracture repair plates and dental appliances. Model created by Kenneth Ip, BEsc and Nikolas Knowles, MESc.

Figure 3 – Skull and jaw bone with 3D printed piston mounts

Figure 3 – Skull and jaw bone with 3D printed piston mounts